Mechanical Fabrication

With the arrival of the third Reinhart generation, the mechanical fabrication made multiple steps forward.

In the years 1952-1999

The cleaning tools were fabricated on conventional machines.

3 axis conventional milling machine

In the years 2000-2006

The method of cleaning tool fabrication was improved to modern CNC machines (2-Axis Lath- and 3-Axis Milling machines with positionnal 4th axis).Production time was reduced and machining quality increased.The new way to machine allowed:- to machine small to big series of parts

- one person to control several machines simultaneously

3 axis milling machin with 4th positionnal axis

2 axis lathe machine

From 2007 to today

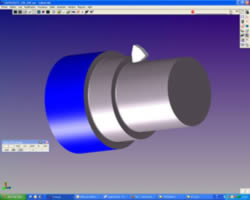

In 2008 RHC SA took another step improving the quality and the flexibility of the machining departement.- Programming with CAM Software (Computer Aided Manufacturing)

- Programming directly on 3D tool parts

- Machines are on the newest state of the art (Combined lathe and milling, 4 axis milling)

Lathe part programming with CAM software

Lathe machine with milling option

From 2009 to today

The company automated the last operations that were handmade over the years by investing in:

- A water-cutting machine

- A leather-cutting machine

- A 5 axis milling machine

- Two 4 axis milling center

Setup of water-cutting machine

5 axis milling center for machining of large parts